-

- Powder Painting Room Air Filter CartridgeSpraying factories use industrial filter elements for powder painting, sand blasting and shot blasting- all processes that produce large amounts of dust pollution. The use of a cartridge filter element is an excellent source for filtration and powder recovery, keeping the manufacturing environment clean. Production workshops within those fields must be equipped with a strong, reliable dust control and dust collection system in order to ensure safety and health of all employees.

-

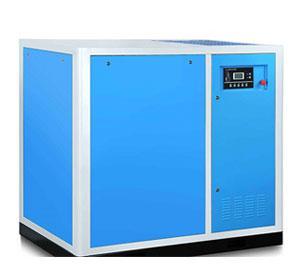

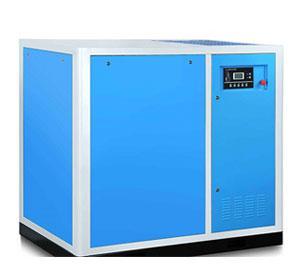

- Filter Panel for Industrial Air CompressorCompressed air containing oil that is produced using air ends will enter a condenser, then after mechanical separation, enters an oil and gas filtration element for filtration. The filter element intercepts and polymerizes the oil in the gas in order to form oil drops that will concentrate on the bottom of the filter element, and return to the compressor’s lubrication system through the oil return line, thus allowing the compressor to exhaust a purer and high quality compressed air.

-

- Filter Cartridge for Cement Plant Dust CollectorOur dust collector filter bags are often used in cement plant dust control systems. Because cement is composed of hard powder particles, the dust will quickly wear out a filter bag, and when there is water in the filter, the cement dust will harden and cake on the filter, leading to the need to frequently replace the filter.

-

- Woodwork Dust Collecting Filter ReplacementWood processing produces a large amount of sawdust, including fine dust caused by dull polishing, and large dust produced through the operation of planer and lathe equipment. Most sawdust is inflammable and a fire hazard, requiring specific air filtration products.

-

- Filter Cartridge for Foundry PlantFoundry plants produce large amounts of smog dust during metal melting, sand blasting and pouring processes. Exhausting, ventilation and dust collection are required to control the level of dust pollutants in workshops in order to keep the working environment clean and safe. Here at Xin Huan Bao, we offer high quality, industrial air filters for dust collection in foundry plants.

-

- Filter Element for Plastics ManufacturingPlastic manufacturing covers a wide array of processes, including plastic blowing, compressing, cutting, grinding, heat sealing, molding, extruding and welding.

Pollutants from plastic processing include wet mist, smog and dust. The dust and fine particles in plastic cutting are of different sizes, and have different properties, which are determined by the plastic type.

-

- Paper Industry Filter Element ProductsXin Huan Bao offers high efficiency filter elements in order to help handle challenges in the paper industry.

As the pulp and paper industry continuously updates equipment used, there are higher demands for high quality efficient lubrication equipment. Lubrication equipment that often fails or does not meet industry needs waste time and money, which is why Xin Huan Bao’s filters are designed to prevent equipment breakdowns due to poor quality lubrication performances.

-

- Filter for Chemical IndustryWithin these industries, most raw materials are very expensive, which makes an integrated recycling device a must to recycle reusable materials in the chemical process. In addition, pollutants from these processes contain a large amount of fog, smog, and dry pollutants that absorb moisture or agglomerate when exposed to the air, which makes dust collection difficult.